Site safety remains our most important parameter for construction projects

Quick Links

1.OVERVIEW

Redefining Construction

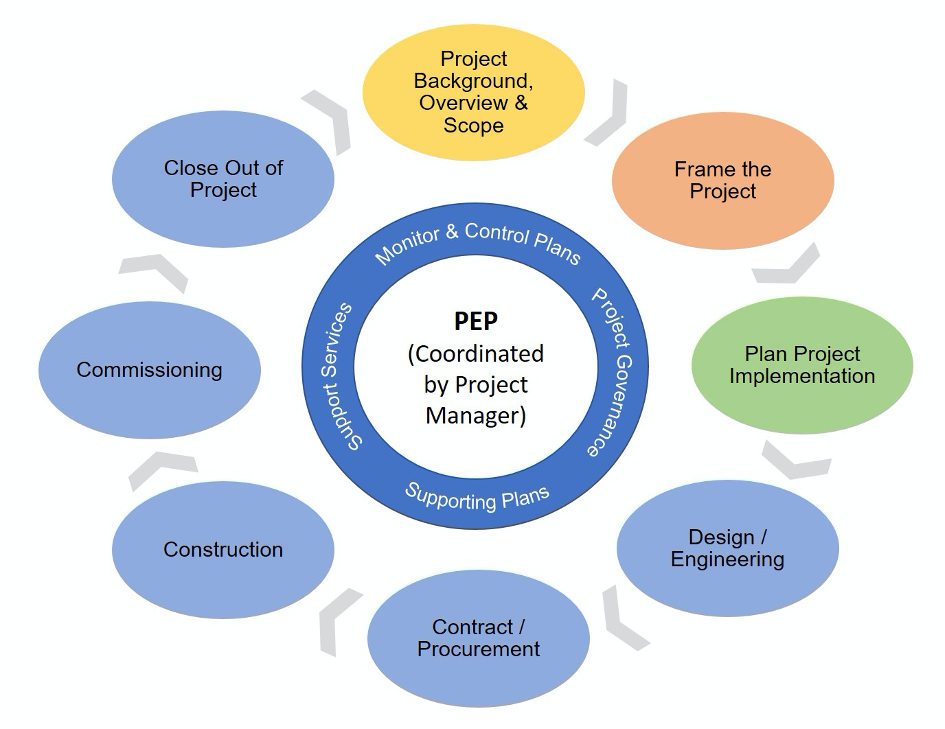

With 10 years of experience, we understand the intricacies of construction planning and execution. Unlike conventional methods, our construction strategy runs in tandem with planning, engineering, and design phases, taking into account the potential service life of a facility, and project parameters such as design codes, geographical conditions, labor supply, etc.

Optimizing the sequence of our turnkey operations minimizes any risk from change orders and re-engineering, resulting in a safe and durable facility.

2.Highlights

3.CAPABILITIES

How we optimize the Production line

- New construction work (green-field projects)

- Brownfield projects (modifications, turnarounds, retrofits, debottlenecking)

- Prefabrication, Modular, stick-built construction

- Piping, Mechanical, Civil/electrical construction

- CM, EPC (EPF, EPCM, EPIC, EPCC), LSTK

- Construction, Maintenance and Operations

- Fixed-price, Unit-price, Cost-plus

- Self-performing, Subcontracting

- Strategic knowledge of construction codes, compliance and labor regulations

- Integrated occupational and QHSE standards throughout the project.

- Full-service engineering center (in Western India)

- Automation/modeling tools for better schedule and risk management.

Hiring of local labor and suppliers to promote economic growth in host countries

4.Modular Construction

- Depending on logistical and other project considerations, we apply modular concepts to applications such as the retrofitting of SO2-abatement technologies into single/double absorption plants, among others.

- Products of different shapes and sizes:

- Hybrid modules

- Small , medium and large modules

- Pipe rack and skid-mounted equipment modules

- Filters, process equipment, pumps, heat media, pipe racks etc.

- Covers all EPC functions— from planning to conceptual design, construction, assembly, transport, testing and subsequent dismantling.

- Self-perform fabrication/modular yards within and outside India

Use of automated designs, ERP and digital tools

-

- Lifetime cost-savings of over 15%

- 20-30% build schedule acceleration

- Simpler designs with less equipment

- Easy to maintain, reconfigure, and adapt to changing industry trends

Better QHSE performance with less waste on-site